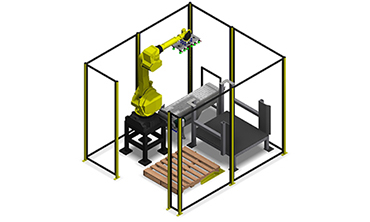

Automated case palletizing increases throughput, improves ergonomics, and provides consistent stacks every shift.

Request Quote| Option | Description |

|---|---|

| Slip / Tier Sheet Placement | Automated placement from magazine |

| Pallet Dispenser | Single or dual pallet stacks with outfeed conveyor |

| Vision / Barcode | Orientation, verification, and traceability |

| MES / PLC Data | Counts, downtime, alarms, recipe audit |

Food & Beverage: Throughput increased 30% and manual lift injuries dropped to zero within six months.